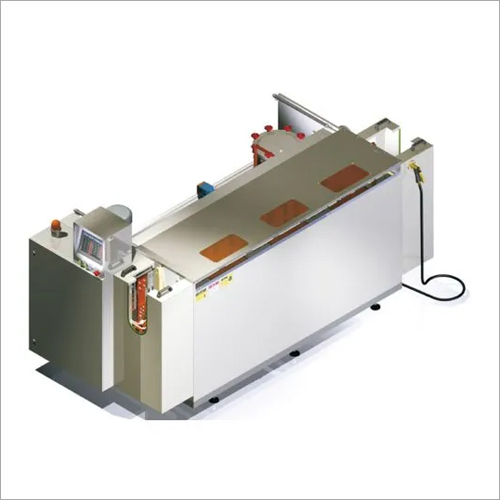

Double Jacket Tank

Product Details:

- Type Double Jacket Tank

- Material MS

- Computerized No

- Automatic Grade Manual

- Size Standard

- Warranty 1 year

- Click to View more

Double Jacket Tank Price And Quantity

- 1 Piece

- 500000.0 INR/Piece

Double Jacket Tank Product Specifications

- No

- MS

- Manual

- Double Jacket Tank

- 1 year

- Standard

Double Jacket Tank Trade Information

- 1000 Piece Per Month

- 7 Days

Product Description

double jacket tankis a specialized type of tank used in industrial processes that require temperature control or heat transfer. It consists of a primary inner tank (the vessel that holds the process material) surrounded by a secondary outer tank (the jacket) that can be filled with a heating or cooling medium, such as water, steam, or thermal fluids. This design allows for more efficient temperature regulation, which is crucial in various applications like mixing, chemical reactions, fermentation, or material storage.

Key Components of a Double Jacket Tank

-

Inner Tank (Process Vessel):

- This is where the raw materials or products are contained. It may hold liquids, chemicals, or slurries, depending on the process.

- The inner tank is typically made of materials resistant to the stored contents, such as stainless steel, which can also withstand temperature changes.

-

Outer Jacket:

- The outer jacket surrounds the inner tank and is separated by an air gap or an insulating layer. The jacket is typically a sealed outer shell that can hold a temperature-controlled medium (hot or cold fluid).

- This jacket provides thermal energy to the inner tank (heating) or absorbs heat (cooling), depending on the application.

-

Inlets/Outlets for Heat Transfer Medium:

- The jacket hasinlet and outlet portsthrough which the heating or cooling fluid circulates. For heating, steam or hot water is often used; for cooling, cold water or chilled liquids may circulate through the jacket.

-

Thermal Insulation (optional):

- Some double-jacket tanks are equipped with insulation around the jacket to prevent heat loss or gain, improving efficiency, especially in temperature-sensitive processes.

How a Double Jacket Tank Works

-

Heating: In processes that require heating, such asmixing,sterilization, orchemical reactions, hot fluid (such as steam or heated water) is pumped into the space between the inner tank and the outer jacket. This transfers heat to the inner tank, which in turn heats the contents inside.

-

Cooling: For processes requiring cooling, likefermentation,storage, orsensitive chemical reactions, cold fluid (such as chilled water or brine) flows through the jacket to absorb heat from the inner tank, lowering the temperature of the contents.

Applications of Double Jacket Tanks

Double jacket tanks are versatile and find applications across various industries, including:

-

Chemical Industry:

- For chemical mixing, reaction processes, or crystallization, where maintaining a consistent temperature is essential for reaction rates and product quality.

-

Food & Beverage Industry:

- In processes like fermentation, brewing, or pasteurization, where precise temperature control is needed to maintain product integrity or optimize microbial activity.

-

Pharmaceutical Industry:

- For mixing or blending chemicals in precise temperature-controlled environments, especially when reactions are sensitive to temperature fluctuations.

-

Cosmetic Manufacturing:

- For the mixing and heating of cosmetic formulations, where stability and temperature control are crucial.

-

Oil and Gas:

- For the mixing and blending of oils, chemicals, or petroleum products, especially when needing to maintain a specific viscosity or chemical reaction temperature.

FAQs of Double Jacket Tank:

Q: What is the type of the tank?

A: The type of the tank is Double Jacket Tank.Q: What is the warranty period of the tank?

A: The warranty period of the tank is 1 year.Q: What is the size of the tank?

A: The size of the tank is Standard.Q: What is the automatic grade of the tank?

A: The automatic grade of the tank is Manual.Q: What is the material used to make the tank?

A: The material used to make the tank is MS.Q: Is the tank computerized?

A: No, the tank is not computerized.Q: What is the capacity of the tank?

A: We cannot provide the capacity of the tank as it is not specified in the product specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Processing Machines And Equipment' category

|

EMAMBIT PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry